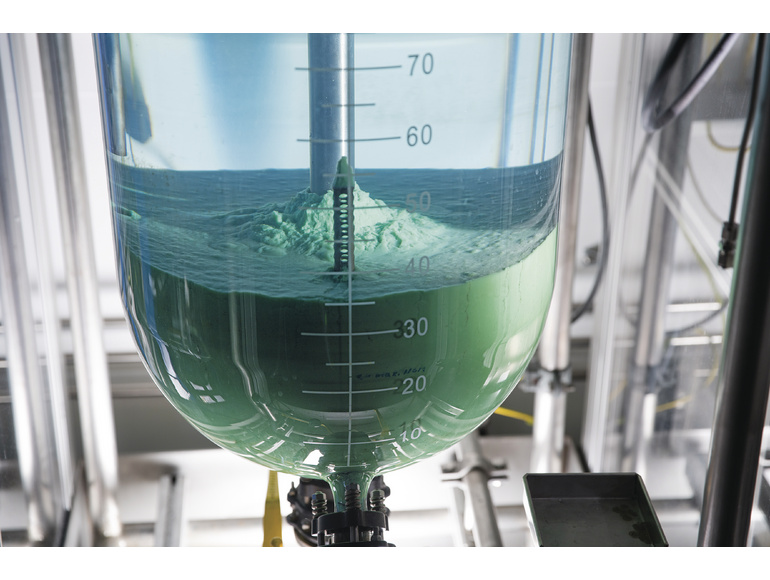

Synthesis of a precursor for a cathode material in the laboratory

The synthesis conditions for cathode materials significantly influence the properties of the end product, such as the range and fast charging capability of a battery. To meet the customers’ requirements, BASF researchers develop individual strategies for the synthesis and post-treatment of the materials.

They have several approaches: Changes in the chemical composition, morphology and synthesis parameters. Cathode materials for lithium-ion batteries usually consist of mixed metal oxides. In the first synthesis step, various metal salts are precipitated with sodium hydroxide and then calcined at more than 700°C. Depending on the required property profile, the cathode materials are additionally post-treated. BASF is a strong player in the battery materials market and runs pilot and production plants in all major regions.Clipdetails

07/09/18

00:02:48

Footage

16:9 HD

Track 1: Atmo,Track 2: Atmo

05/07/18

BASF SE

BASF SE

BASF SE 2018

Downloads

- Timecode-Liste (pdf, 1.06 MB)

- Time code list (pdf, 919.16 KB)

TOP