Shaping the future of electromobility: Research on high-performance battery materials

Electromobility is an important contribution towards addressing global mobility needs – especially in combination with renewable energy. Lithium-ion batteries are used in the majority of today’s electric vehicles. BASF is conducting global research on innovative cathode materials, one of the most important components of these batteries.

Materials for both lithium-ion and all-solid-state batteries

Cathode materials essentially determine efficiency, reliability, costs, durability and the size of the battery. Their properties enable speed, acceleration and power – from compact cars to SUVs, from trucks to buses. BASF’s research includes the synthesis of cathode materials (including precursors), characterization of material properties and performance testing. At the same time, experts are working on components for next-generation batteries, such as all-solid-state batteries.

07/09/18

Synthesis of a precursor for a cathode material in the laboratory

The synthesis conditions for cathode materials significantly influence the properties of the end product, such as the range and fast charging capability of a battery. To meet the customers’ requirements, BASF researchers develop ...

07/09/18

Production of a cathode

Cathode materials offer the broadest innovation potential of a lithium-ion battery as they make the batteries more powerful, reliable and affordable. BASF researchers are thus contributing in the best way to shape the future of ...

07/09/18

Production of a mini test battery (pouch cell): Assembly

To gain insights into the properties of cathode materials produced in the laboratory, BASF researchers use pouch cells. Pouch cells are a common cell type in electric vehicles with a lithium-ion battery. A few hundreds of such ...

07/09/18

Production of a mini test battery (pouch cell): Assembly

To gain insights into the properties of cathode materials produced in the laboratory, BASF researchers use pouch cells. Pouch cells are a common cell type in electric vehicles with a lithium-ion battery. A few hundreds of such ...

07/09/18

Production of a mini test battery (pouch cell): Examination

To gain insights into the properties of cathode materials produced in the laboratory, BASF researchers use pouch cells. Pouch cells are a common cell type in electric vehicles with a lithium-ion battery. A few hundreds of such ...

07/09/18

Exploration of materials for all-solid-state-batteries: Assembly

In addition to cathode materials for lithium-ion batteries, BASF researchers are working on materials for next-generation batteries, such as all-solid-state batteries. Due to their higher thermal stability, they have advantages ...

07/09/18

Exploration of materials for all-solid-state-batteries: Thickness measurement

In addition to cathode materials for lithium-ion batteries, BASF researchers are working on materials for next-generation batteries, such as all-solid-state batteries. Due to their higher thermal stability, they have advantages ...

07/09/18

Exploration of materials for all-solid-state-batteries: Compaction

In addition to cathode materials for lithium-ion batteries, BASF researchers are working on materials for next-generation batteries, such as all-solid-state batteries. Due to their higher thermal stability, they have advantages ...

07/09/18

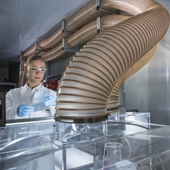

Atmosphere in a research laboratory

BASF runs R&D sites around the world near its customers in Ludwigshafen, Germany; Beachwood, Ohio, U.S.; Shanghai, China as well as Amagasaki and Onoda, Japan.

Contact

+49 621 60-48387

silke.buschulte-ding@basf.com

TV, Photo, Corporate Film, Corporate Footage, TV Service

TOP